PTFE BEARINGS

Bushing MFG has been giving the world options for over 15 years with top-notch PTFE bearings, also known as self-lubricating bearings. These bearings have a self-lubricating feature with very low friction and high wear resistance values to meet all of the needs of our customers.

As a manufacturer of self-lubricating bearings in China, Bushing MFG is providing over 200 million PTFE sliding bearings to dealers and end-users each month. With our team of experts, we offer you a one-stop solution for all designs of PTFE bearings, with various applications, such as agriculture, aerospace, automobiles, elevators, and more.

Bushing MFG: Your Leading PTFE bearings Manufacturer

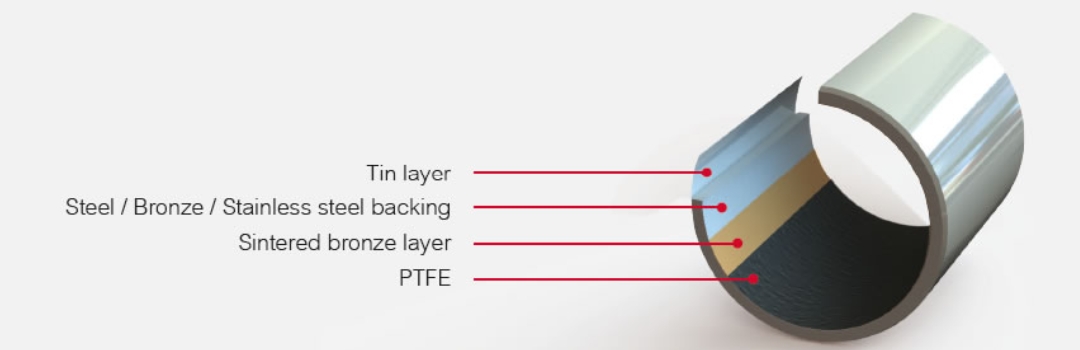

PTFE slide bearings are carbon steel or bronze backed with a sintered bronze layer in the middle and an interior polytetrafluoroethylene (PTFE) layer, which forms a lubricating film to protect the shaft during machine operation. Steel-backed bearings are coated with various metals for protection against corrosion.

These bearings are also known as self-lubricating bushings because they do not need oil to function and can work completely dry. These are fully maintenance-free. By adding a little oil to these bushings you will lower the friction much more and ease the machine working.

The main advantage of PTFE bushings is that they can operate at extreme temperatures, from 195°C to 280°C ( 319° F ~ 536° F ) without expanding or getting brittle. This is because they have very excellent heat dissipation properties. Other benefits include abrasion resistance, low noise, no vibration, no pollution, no water or oil absorption, and last but least, they have thin walls and are lightweight so they can fit in small spaces and reduce the machine’s weight.

Bushing MFG manufactures PTFE sleeve bushes in various designs and shapes, such as sliding plates(strip), half-bearings, thrush washers, flanged bushes, and cylindrical bushes. We can also make any custom shape and size according to the customer’s demands.

PTFE sleeve bearings are widely used in sliding components of different machines, such as motors, automobiles, piston pumps, gear pumps, textile machines, injection molding machines, sports equipment, office accessories, and many more.

Bushing MFG can make its bushings with a lot of different materials according to work conditions. The customer can select the material base according to their needs, such as working environment, load, speed, moving method, installation, or budget. Bushing MFG also provides you with a one-stop solution for both OEM and ODM orders. Whether you are a retailer, distributor or manufacturer, we can always satisfy your needs.

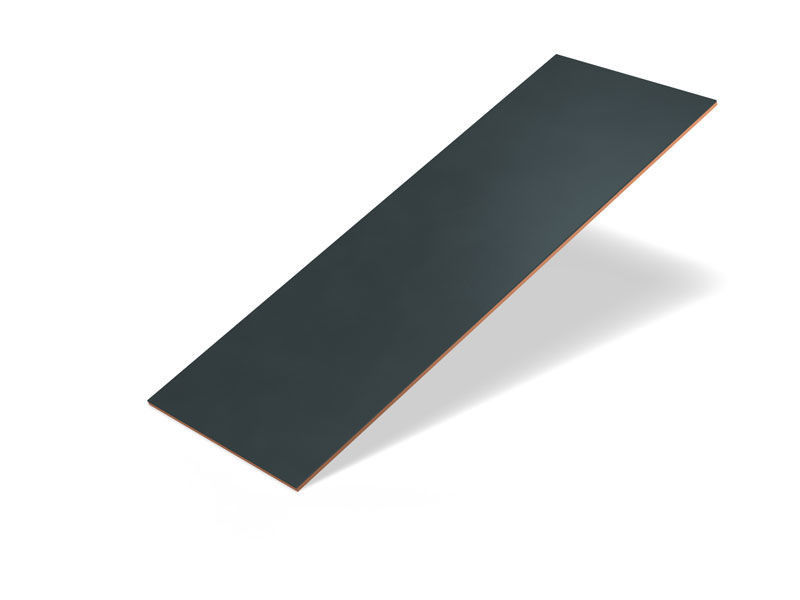

PTFE SLIDING PLATES

These bearings consist mostly of a bronze or steel plate, which is firstly coated with sintered bronze and afterward with PTFE. These have excellent self-lubricating and wear resistance properties.

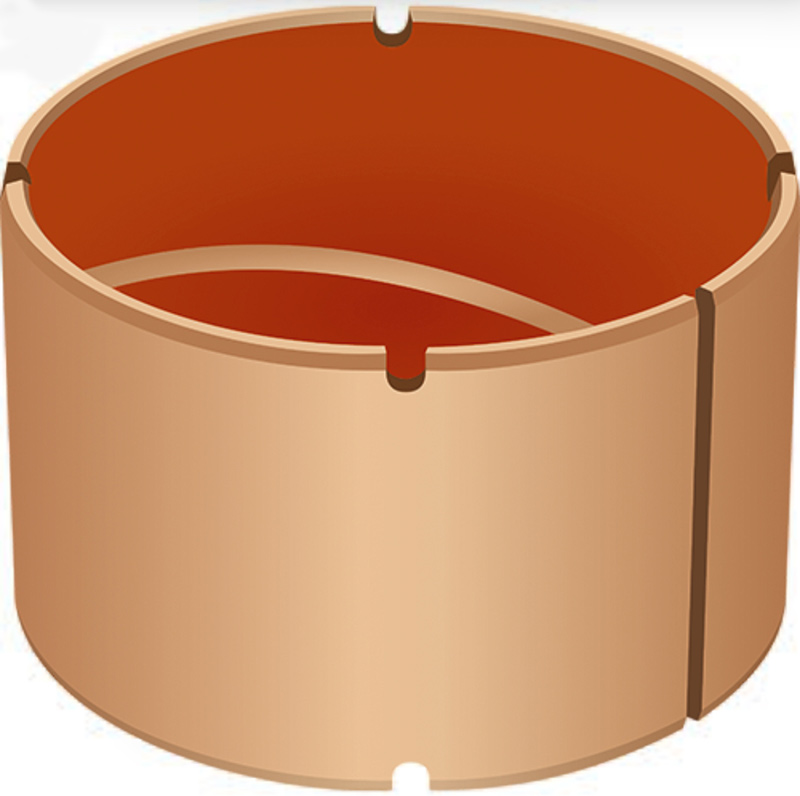

PTFE CYLINDRICAL BUSHES

Cylindrical PTFE bearings are in the shape of cylinders. Their corners are plain. These are used in hydraulics, shock absorbers, gear pumps, fitness equipment, automobiles, e.t.c.

PTFE THRUST WASHERS

Thrust washers are placed between a rotating surface and a fixed part. They allow side to side motion on a shaft and prevent movement along that shaft. They also present a surface on which a bearing is mounted.

PTFE FLANGED BUSHINGS

These are also the same as plain bushings, but flanged thrust washers have a rib, collar, or rim projecting from their corners. A flange is used for strengthening and attachment purposes.

PTFE HALF-BEARINGS

As the name describes, half-bearings are not fully circular, but they are more like half circles. These are used where the load is in one direction and is sufficiently heavy to keep the journal on bearing, such as in railway cars.

CUSTOMIZED BUSHINGS

Apart from the above designs, we can also make bearings completely based on your designs. You can also make changes to the above designs.

PTFE Bearings – The Ultimate FAQs Guide

Bushing MFG is one of the leading non-oil slide bearings manufacturers in China. We not only offer a wide variety of plain bearings, but the rates are highly affordable too.

In this quick and brief guide, you’ll be able to know about the specifications of PTFE slide bearings that Bushing MFG offers.

You can also contact us for more information. So have a look and let us know if you have any questions!

Table of Contents

1. What Is a PTFE Bearing?

PTFE stands for Polytetrafluoroethylene. PTFE bearings have a dry lubricant, PTFE coating as a base material (sliding layer) with bronze, steel, or stainless steel as their backing material.

These are also called self-lubricating or non-oil bearings. As the name suggests, you don’t need to lubricate your bearing off and on. These are maintenance-free bearings that provide lubrication to themselves, during the operation.

Self-lubricating bearings have put an end to the malfunctioning of appliances due to starved lubrication.

Figure 1 PTFE Bearings Different Material Layers

2) What Are The Applications Of PTFE Bearings?

PTFE bearings come in various designs so that they can be used in a wide range of applications.

PTFE bearings are mostly in applications where bearing lubrication can not be done daily, and self-lubrication is needed. PTFE can be used in both light and heavy load areas, but PTFE bearings are very suitable for heavy loads and moderate speeds.

The most famous applications of PTFE bearings are given below;

- Medical

- Railway

- Offshore

- Elevators

- Industries

- Aerospace

- Hydraulics

- Agriculture

- Automobile

- Construction

- Conveyor Belts

- Butterfly Valves

- Textile Machines

- Consumer Electronics

- More

Figure 2.4 Industries

Figure 2.2 Vehicles

3) What Are The Benefits Of Using PTFE Bearings?

Polytetrafluoroethylene ( PTFE ) or Teflon bearings have a lot of advantages over other kinds of bearings.

The very famous benefits of PTFE bearings are given below;

- Maintenance-free

- Have a minimum bearing play.

- Have a low thermal expansion.

- Have good corrosion resistance.

- Can reach a PV value of up to 10,000.

- Have good heat conduction properties.

- Have good electrical insulation properties.

- Can work at an extreme temperature of up to 250°C.

- Absorbs 0% water, making it ideal for moisture areas.

- Highly resistant to alkalis, acids, and almost all other chemicals.

- PTFE sheets have a high load-bearing capacity of 130 kg – 140 kg/ cm2.

- Have high self-lubricating properties and is highly recommended for dry operations or where frequent lubrication is not possible.

- Have a low coefficient of friction. It is discovered that the friction between PTFE and steel is the lowest known friction between two solids.

Figure 3.1 PTFE is Excellent Chemical Resistant

4) What Are PTFE Bearings Made Up Of?

The PTFE bearing has 4 main components;

- Backing

- Protective Layer

- Intermediate layer

- Sliding Layer

- a) Backing

The backing of PTFE bearings is manufactured from one of these 3 materials;

- Steel

- Bronze

- Stainless Steel

Figure 4.1 Steel Backing PTFE Bearing

Figure 4.2 Bronze Backing PTFE Bearing

- b) Protective Layer

In steel-backed PTFE bearings, a thin layer of tin is coated on the outer surface to prevent corrosion. In contrast, bronze-backed bearings do not need a protective layer.

- c) Intermediate layer

There is a layer between the backing and the sliding layer called the Intermediate layer. An intermediate layer is mostly made up of sintered bronze.

A sintered bronze layer is applied to the backing due to the following reasons;

- Ensures efficient heat dispersal

- Ensure strong bonding between backing and sliding surface

5) What Is The Lifespan Of PTFE Bearings?

There are many factors that affect the lifespan of PTFE bearings;

- Size

- Maintenance

- Contaminants

- Working Load

- Production Quality

- And other factors

The lifespan of a PTFE bearing is decreased by contaminants, such as dust, moisture, chemicals, e.t.c. So, it is very necessary to use bearings in a clean environment as much as possible.

The lifespan of PTFE bearings can be greatly increased by frequent maintenance. Lubricating a bearing decreases the chances of wear down by contaminants and increases its life expectancy.

The life expectancy of a bearing is measured by L10 life. L10 life is defined as the number of revolutions or hours that a 90% group of identical bearings can survive before they expire.

Most PTFE bearings can survive 4 – 5 times more than their L10 lifespan. they are can be used for 8 – 12 years.

6) What Is The Price Of Our PTFE Bearings?

The price depends on the following factors;

- Material used

- Size of Bearing

- Design of Bearing

- a) Material Used

PTFE bushings have either steel or bronze or stainless steel backing.

Bronze is expensive than steel because;

- Bronze is 10% denser than steel.

- Bronze is also resistant to corrosion while steel is not.

- Bronze is a better conductor of heat and electricity than steel.

- And more.

So, bronze bearings may be costly, but they also work better and run longer than steel bearings.

- b) Size of Bearing

The price of a bearing also depends upon its size. Large size bearings will be costlier than small size bearings because large-size bearings use more material and work hours to manufacture.

- c) Design of Bearings

Complex design bearings are more costly than simple design bearings.

- d) Customization

Adding a personal logo will also add a little money to the overall price of bearings.

The average price of Bushing MFG Bearings is: $0.5 – $3

Figure 5 Cost Of PTFE Bearings

7) What Are The Specifications Of PTFE Bearings?

Shaft hardness, shaft roughness, max sliding speed, max load capacity, friction coefficient, thermal conductivity, linear expansion coefficient, operating temperature range, shaft, and housing tolerance values. asking our sales for the newest catalog.

8) What Certificates Do We Have For PTFE Bearings?

Our factory has 1S0 1900-2015, RoHS, SGS, TSI-16949, and TUV certificates, which means we always ensure strict quality checks during manufacturing.

9) Can You Customize Your Own PTFE Bearings?

Yes, we can produce any kind of bushings. We have both OEM and ODM services available. We at Bushing MFG have 10+ years of experience in manufacturing different designs of bushings for various applications.

You can see the chart below to customize your own PTFE bearing according to your needs;

10 ) What Are The HS Codes Of PTFE Bearings?

HS codes are internationally accepted 6 – 10 digits codes that are used to determine the custom tariffs on imported products.

Custom duties change from time to time and are different for each country.

This is where HS codes become helpful. You can give your bearings HS codes to your government, and they will provide you with an exact cost of customs duties.

The HS code of our PTFE bearings is : 8483300090

11) What Is The Delivery Time Of PTFE Bearings?

The delivery time of your order depends on factors:

- Order Volume

- Shipment duration

We can produce 200 million bearings per month. So, If you choose our standard designs, we can manufacture, inspect, and pack them on the same day. But if you have a custom design, it will take up to 15 days for its production.

Then after that, the delivery time will depend upon shipment duration. Due to the coronavirus pandemic, shipment may take more than 30 days.

Inform us in advance if you have urgent orders. We can increase our working hours and will complete your orders on the assigned dates.

12) Why Are Our PTFE Bearings Better Than Local Ones?

Bushing MFG’s PTFE bearings have the following advantages over other local ones;

- Affordable

- Fast Delivery

- Easy to install

- Maintenance-free

- Designed by best engineers

- Have no minimum order limits

- Longer Lifespan of 8 – 12 years

- Manufactured from best materials

- Come in various designs and sizes

- Have both OEM and ODM services

- Have very low coefficient of friction

Get an Instant Quote