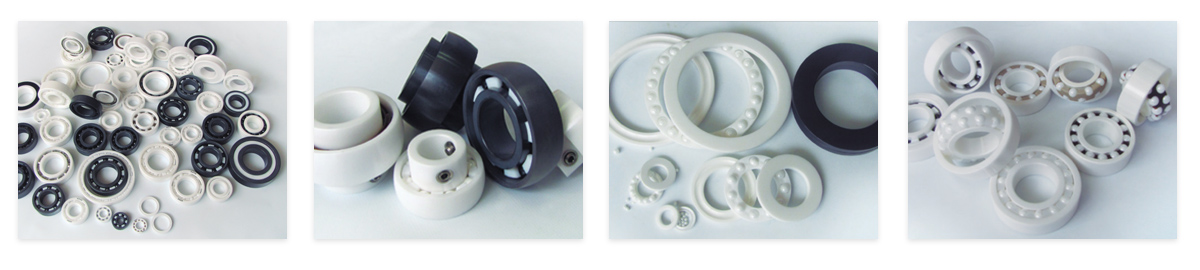

Ceramic Bearings

Ceramic bearings are a perfect choice if your operating environment requires high temperature, cold, easy corrosion, high speed, and self-lubricating conditions, This is why it can be widely used in high-tech fields such as aerospace, automobile, chemical industry, electric power, medical equipment, etc. In addition, the main features of ceramic bearings are high bearing capacity, good heat resistance, high limit speed, small friction heating during operation, small friction loss, high durability, and good corrosion resistance. talk to our engineer team for professional advice on how to choose the correct ceramic bearing types.

Ceramic Ball Bearings Series

Deep Groove Ceramic Ball Bearing (Miniature Ceramic Ball Bearings)

Metric Series:

Full Ceramic Bearings

Full ceramic bearings are usually made of four materials: zirconia (ZrO2), silicon nitride (Si3N4), hydrofluoric acid resistance, wear-resistant silicon carbide (SiC), 99% alumina (AI2O3). Each material has its own specific advantages in the use environment. also full complete ceramic bearing and ZrO2 cage full complete ceramic bearing, Bushing MFG can design according to the requirements of different customers no matter full ceramic or hybrid ceramic.

Ceramic Bearings Things To Know

Bushing MFG is a ceramic product manufacturer since 2006, we provide high-quality ceramic products with cheap prices, overall million pieces stock for directly buying, and rich experience for designing your special need.

What are advantages and disadvantages of ceramic bearings?

Ceramic bearings are used as mechanical equipment parts, which have their own advantages and disadvantages. In order to further understand the ceramic bearing, let’s take a look at its advantages and disadvantages:

Advantages

- Corrosion resistance

Ceramic bearing is a corrosion-resistant mechanical component, Compared with other materials, ceramics have higher corrosion resistance, so they are especially suitable for working in corrosive conditions

- Stable performance

It can work normally in an environment with severe temperature differences because the ceramic bearing is not affected by high temperature and low temperature.

- Not easily deformed

The elastic modulus of ceramics is high, there will be no deformation under force, and high accuracy is maintained in high-speed usage scenarios.

- Long service life

Ceramic bearings are more durable than other types of bearings and are made of ceramic balls which are coated with metal. They have a much longer service life than other types of bearings, which means they can last for up to 5 times longer.

Disadvantages

- Difficulty in processing

Ceramic bearings have a lower load-carrying capacity and are more sensitive to thermal shock than metal. Therefore, when processing ceramic bearings, the processing steps are very complicated, and there are many factors to be considered. Therefore, one of the disadvantages of ceramic bearings is the difficulty of processing.

- High cost

Ceramic bearings are non-metallic and non-ferrous materials and are a kind of non-magnetic excellent insulator, so the cost of ceramic bearing materials is relatively high. At the same time, the processing and grinding costs of ceramic bearings are very complicated, so the production cost of current ceramic bearings is also very high. Therefore, the most obvious disadvantage of the current ceramic bearings is the high cost.

Are ceramic bearings better than steel?

full ceramic bearings fatigue life is 10-50 times than full steel bearings, and the life of hybrid ceramic bearings is 3-5 times higher than that of steel bearings, so the durable of ceramic bearings is higher than that of steel bearings, compared to steel bearings ceramic bearings are more wear-resistant, and the ceramic material itself is more corrosion-resistant than steel.

Ceramic is a self-lubricating material, so in the absence of lubricating oil, the lubricating ability of ceramic bearings is not lower than that of steel bearings that have used traditional lubricants. In addition, the rigidity of ceramics is greater than that of steel (the rigidity of ceramic bearings is greater than that of ordinary bearings), and the elastic modulus is higher than that of steel bearings.

Do ceramic bearings make a difference?

Ceramic bearings are a type of bearing that has ceramic balls instead of metal. They are used to reduce the amount of friction and increase the lifespan of the bearing.

Ceramic bearings can be found in many different types of machinery including cars, trains, planes, and other types of vehicles. They are also found in many different types of appliances such as dishwashers, air conditioners, refrigerators, and vacuum cleaners.

There are many benefits to using ceramic bearings rather than metal bearings. For one thing, they can last up to 10 times longer than traditional metal bearings; this is because they use less friction which means less wear on the bearing itself. Ceramic bearings also produce less noise than traditional metal bearings which makes them great for machines like dishwashers where you want it to be

Is ceramic bearing worth it?

The answer is that ceramic bearing really worth it.

For four reasons:

1: Ceramic is a corrosion-resistant material, so ceramic bearings are ideal for use in harsh conditions that are extremely corrosive.

2: Compared with steel balls, the density of ceramic balls is lower, so the overall ceramic bearing is much lighter than the stainless steel bearing, so the centrifugal effect of the outer ring can be reduced by up to 40% during use, which is why the service life of the ceramic bearing is relatively long.

3: The influence of thermal expansion and cold contraction on ceramics is relatively small, so when the bearing clearance is certain, ceramic bearings can work normally in an environment with a large temperature difference.

4: Ceramics have high elasticity and are not easily deformed when subjected to force, so they maintain high precision under high-speed operation.

Why are ceramic bearing so expensive?

Ceramic bearings are much more expensive than regular bearings because they have a higher quality, which means they last longer and perform better in extreme temperatures. This also means that the cost per year for these bearings will be less than for regular ones, which could make it worth the price for some people who want to invest in a better product.

Get an Instant Quote