Last Updated on September 5, 2024 by Chen

Yes, teflon is self lubricating material for bushings, And teflon (PTFE – polytetrafluoroethylene) is known for its unique set of characteristics. Low friction coefficient, nonstick surface, chemical resistance, high temperature resistance, electrical insulation.

Teflon (PTFE) Bushing features

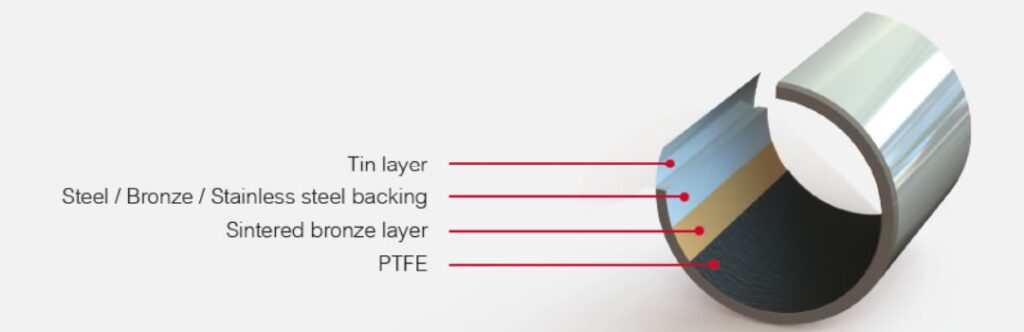

Teflon, short of (PTFE) Polytetrafluoroethylene, is a key component in PTFE bushings. These bushings feature a dry lubricant in the form of a PTFE coating, which serves as the primary sliding layer. They are typically reinforced with backing materials such as bronze, steel, or stainless steel to enhance their strength and durability.

Dry Lubrication: PTFE bushings use a PTFE coating as a sliding layer, providing low friction without the need for external lubrication.

Maintenance-Free: These bushings are often referred to as self-lubricating or oilless bearings, as they do not require regular lubrication and are designed to be maintenance-free.

Durable Backing Materials: Typically backed by materials such as bronze, steel, or stainless steel, which enhance their structural strength and durability.

Reduced Friction: The PTFE coating ensures a low friction coefficient, which reduces wear and tear on moving parts.

Prevention of Lubrication Starvation: Self-lubricating design eliminates issues related to inadequate or missing lubrication, preventing malfunctions in machinery.

Wide Temperature Range: Capable of operating effectively across a broad range of temperatures.

Chemical Resistance: Resistant to many chemicals and harsh environments, making them suitable for various industrial applications.

Applications of Teflon Self-Lube Bushings

- Medical: Essential in devices requiring low friction and high reliability, such as surgical instruments and diagnostic equipment.

- Railway: Ensures smooth and maintenance-free operation in train components.

- Offshore: Resists harsh marine environments and contributes to the longevity of equipment.

- Elevators: Provides smooth and quiet performance in elevator systems.

- Industry: Enhances efficiency and reduces maintenance needs in various industrial applications.

- Aerospace: Handles high temperatures and reduces friction in aerospace components.

- Hydraulics: Withstands high pressure and ensures durability in hydraulic systems.

- Agriculture: Performs reliably under tough conditions in agricultural machinery.

- Automotive: Reduces friction and extends the lifespan of automotive parts.

- Construction: Used in structural elements for its reliability and low maintenance needs.