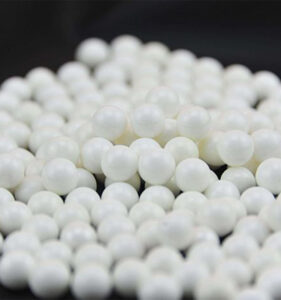

Ceramic Balls

Ceramic Balls are a type of bearing material. They are used in a wide range of applications, from high-speed Šī iepriekšēja pārbaude palīdz izveidot bukses atbilstoši pielietojumam Šīs bukses nodrošina izcilu noguruma izturību un nestspēju applications.

Ceramic balls have many advantages over metal bearings. They have a higher load capacity and can operate at higher speeds, as well as being able to operate at higher temperatures with less wear and tear. Ceramic Balls also offer corrosion resistance for use in wet environments such as marine environments or corrosive atmospheres such as those found in chemical plants.

Material of Ceramic Balls

Zirconium oxide ceramic balls (ZrO2)

Apart from concentrated acids and hot, dilute hydrochloric acid, zirconia balls are typically resistant to abrasive compounds. The maximum practical range of zirconia is 1800° F. Compression strength Force. 784,837 psi is a pressure of 794,838 psi. Zirconium applications include dyes milling and crankshafts operations.

Precision Metal Ball Sector manufactures quality tiny balls of zirconium dioxide (ZrO2), titanium, Šīs bukses nodrošina izcilu noguruma izturību un nestspēju, and polymer. For a spectrum of uses, designers provide a lot of quality zirconia balls with diameters ranging from 1/9″ C, pamatojoties uz modeli 1 inch thick. The hardness of zirconium dioxide gave it high strength.

Silicon Nitride balls (Si3n4)

In industries where extremely high gyration is essential, silicon nitride balls have been employed in complete ceramic as well as hybrid-ceramic bearings. Because silicon nitride has a thickness less than 1⁄2 that of titanium, it reduces angular momentum during bearings revolution, allowing for higher working temperatures.

Alumina Oxide Balls (Al2O3 ceramic)

Alumina ceramic balls are 99.99% Alumina ball that has high corrosion resistance capabilities and operate under high temperatures. It has high stability and is used in heavy-duty automobile industries. It has a wide range of applications in the automobile industry where bearings for the valves of different IC engines are required. The precision metal ball industry has a wide range of aluminum oxide ball bearings. It supplies ceramic alumina balls in every dimension.

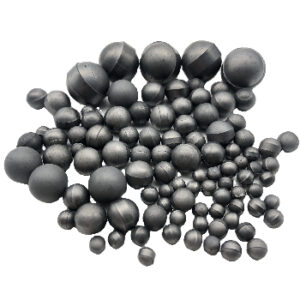

Silicon Carbide Balls (SiC ceramic)

Silicon carbide balls have excellent mechanical and tensile capabilities, strength and durability, and wear resistance. They are good conductors of electricity that can withstand extreme temperatures. It has application in the aviation and electronics industries. Silicon carbide ceramics have an ultimate compressive strength of 1700-2225.

Ceramic Ball Things To Know

Bushing MFG is a ceramic product manufacturer since 2006, we provide high-quality ceramic products with cheap prices, overall million pieces stock for directly buying, and rich experience for designing your special need.

What Are Ceramic Balls Used For?

Ceramic balls are used as the rolling element in a bearing. They can be used as a bearing for many different types of machinery, such as:

-rolling mills

-cement mills

-papīrfabrikas

-traction engines

-steam locomotives

Ceramic balls come in three different grades: grade 3, grade 10, and grade 20. Grade 3 is the cheapest and most common type of ceramic ball. Grade 10 is less expensive than grade 20 and is often used in heavy-duty applications like traction engines and steam locomotives.

Ceramic Balls vs. Steel Balls

The difference between ceramic balls and steel balls is that the former are lighter, have a lower coefficient of friction, and can absorb more shock from impacts.

Ceramic balls tend to be a lot lighter than steel balls, which means they can be more easily manipulated by a player. Ceramic also has a lower coefficient of friction which means it usually has an easier time rolling on the table surface. This low friction property also means that there is less of a chance for the ball to slip off an edge as well as be able to absorb more shock from impacts.

The best ceramic ball bearings manufacturers in China

Bushing MFG is the ultimate destination for precision ceramic balls, which are manufactured using the latest in the industry-leading technology and competitive price. Bushing MFG also is one of the leading suppliers of ceramic balls, and they offer a wide range of products such as light-duty ceramic bearings, heavy-duty ceramic bearings, and seals to meet your needs. Contact our sales team now!

Saņemiet tūlītēju cenu savam nākamajam Graphite pašeļļojošo bukses pasūtījumam