Last Updated on September 26, 2024 by Chen

glidlager utan olja

5 Types of Roller Bearings – Roller bearings are essential components in mechanical systems that reduce friction and support radial and axial loads. They facilitate smooth and efficient rotational motion between different parts of a machine. The type of roller bearing selected depends on the specific application and operational demands. Choosing the right roller bearing is crucial to ensure optimal performance, reliability, and longevity of your equipment. Typically made from high-quality steel, roller bearings are engineered to withstand high speeds and heavy loads.

Bussning MFG offers a wealth of information and resources on roller bearings. No matter your application or industry, we can help you identify the most suitable roller bearings for your needs. Bussning MFG provides a diverse range of Roller Bearing Products to ensure you find one that meets your specifications.

On HS-koden för våra PTFE-lager är website, you’ll find a comprehensive list of roller bearings available for all Original Equipment Manufacturer (OEM) requirements. Our expert team is ready to assist you in navigating our extensive inventory. Please get in touch with our Roller Bearing Specialists to learn more about sourcing high-quality products from a diverse range of trusted suppliers. Bussning MFG also offers a cost-free quotation request service from our network of Roller Bearing Suppliers and Companies if you’re interested in obtaining pricing information.

What Is a Roller Bearing?

A roller bearing is a type of rolling-element bearing that uses cylindrical, tapered, or needle-shaped rollers to maintain the separation between moving parts of the bearing. Unlike ball bearings that utilize spherical elements, roller bearings employ rollers to handle heavy radial loads and reduce friction between rotating shafts and stationary components. They are essential in various mechanical applications, providing high load-carrying capacities and efficiency in industrial machinery.

There are five main types of roller bearings: Cylindrical Roller Bearings, Needle Roller Bearings, Spherical Roller Bearings, Tapered Roller Bearings, and Thrust Roller Bearings. Each type is engineered to meet specific load conditions and application requirements. Typically constructed from high-grade steel, roller bearings are chosen for their durability, reliability, and ability to perform under high-speed and high-load conditions.

Roller bearings can be classified based on the direction of the load they support—radial, axial (thrust), or a combination of both. Some are designed exclusively for radial loads, while others can accommodate axial or combined loads. Selecting the appropriate roller bearing is crucial to ensure optimal performance, longevity, and safety of your equipment.

We’ve prepared a detailed overview of the most prevalent types of roller bearings, along with their components and applications. But first, let’s take a brief look at the fundamental components that make up a roller bearing.

Types of bearings (Reference: pinterest.com)

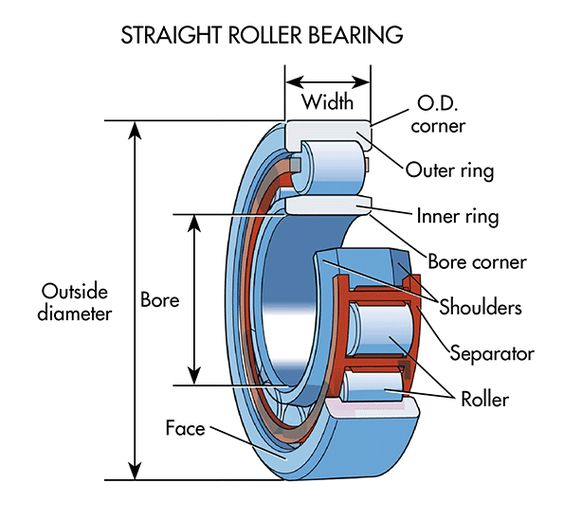

Roller Bearing Components

Here is a short explanation of basic terms before we discuss the various types of roller bearings:

- Inner Ring: The inner circular component that fits onto the rotating shaft.

- Outer Ring: The outer circular component that encases the rollers and fits into the housing.

- Rollers: The rolling elements that move between the inner and outer rings to reduce friction.

- Cage: The component that separates and guides the rollers, keeping them evenly spaced.

- Raceways: The tracks on the inner and outer rings where the rollers roll.

- Seals/Shields: The parts that prevent contaminants from entering the bearing and retain lubrication.

- Lubrication: Grease or oil used to minimize friction and wear between the bearing components.

Different Component Parts of roller bearing (Reference: machinedesign.com)

Types of Roller Bearings

The 5 main types of roller bearings include:

- Cylindrical Roller Bearings

- Needle Roller Bearings

- Spherical Roller Bearings

- Tapered Roller Bearings

- Thrust Roller Bearings

Cylindrical Roller Bearings

Cylindrical roller bearings feature rollers that are essentially cylindrical in shape, but with slightly crowned surfaces to reduce stress concentrations. These bearings are capable of supporting heavy radial loads and are suitable for high-speed applications. They consist of inner and outer rings with cylindrical rollers in between, and they provide low friction and long service life. However, they are not designed to handle significant axial (thrust) loads.

Cylindrical roller bearings are commonly used in electric motors, gearboxes, and machine tool spindles where high radial load capacity and speed are required.

Needle Roller Bearings

Needle roller bearings are similar to cylindrical roller bearings but have rollers that are much thinner and longer relative to their diameter. This design allows for a compact bearing with high load-carrying capacity. They are ideal for applications where radial space is limited but a high radial load capacity is needed.

These bearings are often found in automotive transmissions, pumps, and compressors due to their ability to handle heavy loads in compact spaces.

Spherical Roller Bearings

Spherical roller bearings have barrel-shaped rollers that are self-aligning, allowing them to accommodate misalignment between the shaft and housing. They can support heavy radial loads and moderate axial loads in both directions. The self-aligning feature reduces maintenance costs and downtime due to misalignment issues.

Spherical roller bearings are suitable for applications like heavy machinery, mining equipment, and paper mill equipment where shaft deflection or misalignment can occur.

Tapered Roller Bearings

Tapered roller bearings consist of tapered inner and outer ring raceways, along with tapered rollers. This design enables them to support combined radial and axial loads. The bearings can be adjusted to fine-tune the preload and clearance, enhancing performance and longevity. The contact angle determines the axial load capacity—the larger the angle, the higher the axial load it can support.

Common applications include automotive wheel hubs, gearboxes, and axle systems where both radial and axial loads are present.

Thrust Roller Bearings

Thrust roller bearings are designed specifically to handle high axial loads in one direction. They consist of two raceways and rollers oriented to accommodate axial stresses. The rollers can be cylindrical, spherical, or tapered, depending on the specific bearing design. They provide high rigidity and can support heavy thrust loads.

These bearings are used in applications like crane hooks, rotary tables, and heavy-duty machinery where significant axial load capacity is required.

Download Types of Roller Bearings PDF

There is an option to download the article in PDF format if you find that to be more convenient for you. You can download the file by visiting the following link.

Buy Bearing/Bushing or Ask for a Service

By using Bushing MFG’s RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Visit our website to request a quotation from suppliers and service providers.