Last Updated on October 30, 2024 by Чен

A bearing sleeve, often referred to as a sleeve bearing, is a type of plain bearing that facilitates smooth movement between two components by reducing friction.

Types of bearing sleeve

Following is the comprehensive bearing sleeve types we need to talk about,

Бронзовые втулки

- Material: Made from bronze, which is known for its strength and durability.

- Приложения: Often used in high-load, low-speed applications, such as pumps, industrial machinery, and electric motors.

- Преимущества: Great wear resistance, good load-bearing capacity, and good resistance to corrosion.

Flanged Bushings

- Design: Features a flange (or lip) at one end to help position the bushing or offer a load-bearing surface.

- Приложения: Common in situations where axial loads are present in addition to radial loads.

- Преимущества: Helps prevent axial movement and provides additional support.

Пластиковые втулки

- Material: Made from high-performance plastics like nylon or PEEK.

- Приложения: Often used where lubrication is difficult or undesirable.

- Преимущества: Lightweight, corrosion-resistant, and low maintenance. These bushings also reduce noise and have good chemical resistance.

Neoprene Bushings

- Material: Made from neoprene, a type of synthetic rubber.

- Приложения: Used in vibration-damping applications, like automotive suspension systems or marine environments.

- Преимущества: Excellent flexibility and resistance to weather, oil, and chemicals.

Втулки из ПТФЭ

- Material: Made from polytetrafluoroethylene (ПТФЭ), which is a non-stick material.

- Приложения: Used in high-temperature environments and situations requiring low friction.

- Преимущества: Self-lubricating, excellent thermal stability, and resistant to wear and chemicals.

Steel Bushings

- Material: Made from steel, offering high strength.

- Приложения: Used in heavy-duty applications requiring high load capacity, such as agricultural machinery or heavy equipment.

- Преимущества: Extremely durable and has high load-carrying capacity, but requires lubrication to prevent wear.

Thrust Washers

- Design: Flat washers used in combination with bushings to handle axial loads.

- Приложения: Used in assemblies that require resistance to thrust or axial loads.

- Преимущества: Increases the lifespan of the bushing system by reducing wear and absorbing axial forces.

Cylindrical Bushings

- Design: Simple cylindrical shape that allows for radial load distribution.

- Приложения: Used in a wide range of applications, including automotive and industrial machinery.

- Преимущества: Easy to install and remove, suitable for radial loads.

Графитовые втулки

- Material: Contains graphite, which acts as a lubricant.

- Приложения: Used in high-temperature or dry-running conditions where other lubricants fail.

- Преимущества: Self-lubricating and excellent for applications that experience extreme temperatures.

Metallic Self-Lubricating Bushings

- Design: Infused with solid lubricants, like graphite or ПТФЭ.

- Приложения: Ideal for applications where external lubrication is impractical, such as in aerospace and automotive industries.

- Преимущества: Maintenance-free and offers a long service life with low friction.

POM Bushings (Polyoxymethylene)

- Material: Made from engineering thermoplastic known as polyoxymethylene (POM).

- Приложения: Used in applications requiring high dimensional stability and low friction.

- Преимущества: Good mechanical strength, low friction, and resistance to abrasion.

Sliding Plates

- Design: Flat, plate-like components that allow for sliding motion.

- Приложения: Used in bridge structures, heavy machinery, and construction for load-bearing with sliding functionality.

- Преимущества: Offers low friction and wear resistance in large sliding motions.

Aluminum Bushings

- Material: Made from aluminum, offering lightweight properties.

- Приложения: Often used in applications where weight reduction is critical, like aerospace and automotive.

- Преимущества: Corrosion-resistant, lightweight, but not as strong as steel.

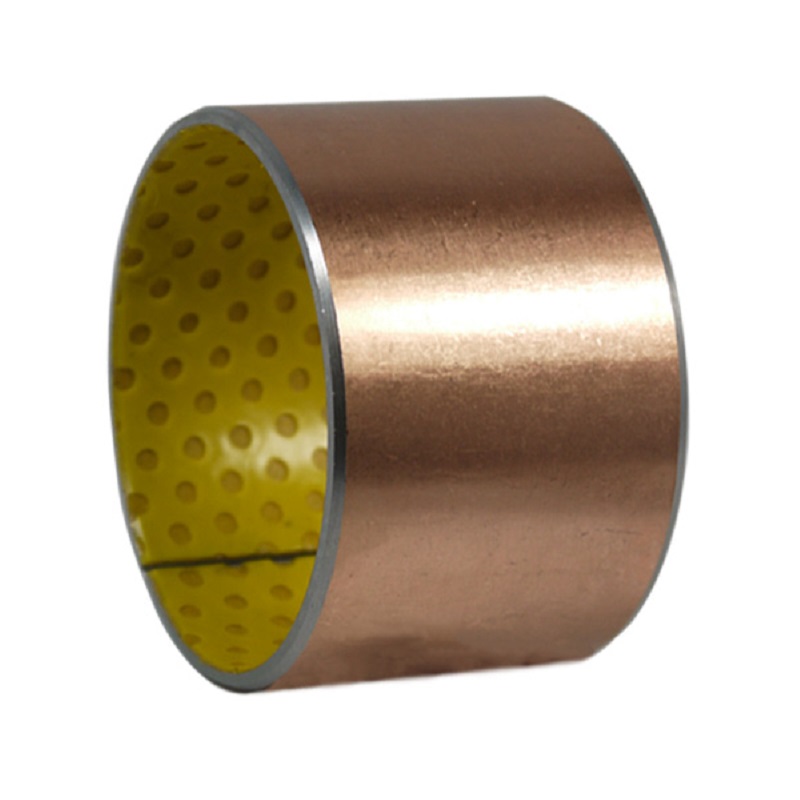

Биметаллические втулки

- Material: Made by combining two different metals, typically steel backed with a bronze or other alloy layer.

- Приложения: Used in high-load, low-speed applications such as automotive engine components.

- Преимущества: Combines the strength of steel with the anti-friction properties of softer metals like bronze.

Brass Bushings

- Material: Made from латунь, which has good machinability and corrosion resistance.

- Приложения: Often used in plumbing, электрический, and industrial machinery due to its resistance to water and oils.

- Преимущества: Good wear resistance, corrosion-resistant, and easily machinable.

Composite Bushings

- Material: Made from a combination of materials such as plastics reinforced with fibers.

- Приложения: Used in industries where lightweight and low friction are critical, such as automotive or aerospace.

- Преимущества: Lightweight, self-lubricating, and corrosion-resistant.

Фланцевые втулки

- Design: Same as flanged bushings mentioned above.

- Приложения: Used where both axial and radial loads need support.

- Преимущества: Easy to position and support with additional load-bearing capacity on the flange.

Nylon Polymer Bushings

- Material: Made from nylon, a durable plastic polymer.

- Приложения: Suitable for applications requiring resistance to wear, chemicals, and moisture, such as conveyor systems or water applications.

- Преимущества: Self-lubricating, corrosion-resistant, and offers excellent noise reduction.

Are you looking for high-quality bushings that enhance the efficiency and longevity of your machinery? At Bushing MFG, we specialize in manufacturing top-tier bearing sleeve types tailored to meet your specific needs.